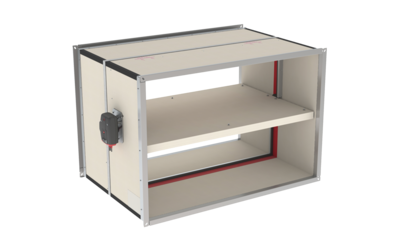

The CU2L type fire damper is designed to be installed in ventilation ducts through a wall to prevent the spread of fire between 2 different areas.

The body of the damper is longer to prevent the flap from protruding from the damper.

Advantages and construction features

- The body of the damper is made of refractory material, free of asbestos, and is long enough to prevent the flap from protruding from either of its 2 sides.

- The control mechanism is offset from the centre of the damper, allowing for perfect insertion into the wall. The mechanism will be installed on one side of the wall, making it easy to access and manipulate.

- Moisture-resistant material.

- Foam sealing gasket to prevent smoke from escaping.

- Intumescent gasket that welds the flap to the body of the damper in the event of a fire.

- Possibility of different types of duct connection.

- Maximum temperature of the air conducted under normal conditions 70ºC.

- Class B tightness.

CU2L+CFTH: CU2L rectangular damper with a trigger mechanism that activates the closing of the damper only by melting the fuse set at 72ºC or by activating the lever located on the mechanism itself (reset in case of triggering must be carried out from the damper itself using an Allen key).

CU2L+CFTH+FDCU: CU2L rectangular damper with CFTHA and limit switch.

CU2L+ONET24 FDCU: 24V motor with return spring. When power is applied, the servomotor activates the blade, bringing it to the standby position (open). When the power supply is interrupted or when the duct temperature exceeds 72ºC, the energy accumulated by the spring tension brings the damper blade to the safety position (closed). The motor is reset using a standard 9V battery. The start and end contacts (included) indicate the open/closed position of the slat.

CU2L+ONET24-ST FDCU: ONET spring-return motor with standard ST connector.

CU2L+ONET230 FDCU: 230V spring-return motor. When the power is applied, the servomotor activates the slat, bringing it to the standby position (open). When the power supply is interrupted or when the temperature of the duct exceeds 72ºC, the energy accumulated by the spring tension brings the damper slat to the safety position (closed). The motor is reset using a standard 9V battery. The start and end contacts (included) indicate the open/closed position of the slat.